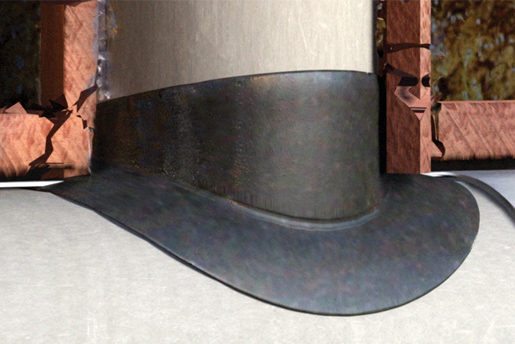

Insignia Hydrophilic Connection Hat

- Home

- /Insignia Hydrophilic Connection Hat

Key Features:

The Insignia™ Hydrophilic Connection Hat is utilized to provide a positive compression seal at the main-to-lateral junction of a sewer collection system. This hat is a 360 degree sealing gasket that prevents water tracking behind the liner at the main-to-lateral junction of a collection system where the maximum amount of infiltration and inflow (I&I) occurs. The Insignia Hydrophilic Connection Hat creates a seal at the main source of infiltration ensuring that this sealing technology, along with a structural CIPP repair, is the most effective solution for rehabilitating the main-to-lateral connection. The Insignia product line used in conjunction with CIPP lining is more than just a structural repair; it’s a water-tight sealed system!

ASTM F3240

Significance and Use

Purchase the full version of this standard by visiting the ASTM website here.

This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations that are involved in the rehabilitation of main and lateral pipelines and manholes. As for any practice, modifications may be required for specific job conditions.

1. Scope

- This practice covers the requirements for the installation of seamless molded hydrophilic gaskets (SMHG) in cured in place pipe (CIPP) rehabilitation of main and lateral pipelines.

- The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

- There is no similar or equivalent ISO Standard.

- This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

- This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

- D1149 Test Methods for Rubber Deterioration-Cracking in an Ozone Controlled Environment

- D1600 Terminology for Abbreviated Terms Relating to Plastics

- D2240 Test Method for Rubber Property-Durometer Hardness

- F412 Terminology Relating to Plastic Piping Systems

- F1216 Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube

- F1743 Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

- F2019 Practice for Rehabilitation of Existing Pipelines and Conduits by the Pulled in Place Installation of Glass Reinforced Plastic (GRP) Cured-in-Place Thermosetting Resin Pipe (CIPP)

- F2599 Practice for The Sectional Repair of Damaged Pipe By Means of An Inverted Cured-In-Place Liner

- F2561 Practice for Rehabilitation of a Sewer Service Lateral and Its Connection to the Main Using a One Piece Main and Lateral Cured-in-Place Liner

2.2 NASSCO Guidelines:

Recommended Specifications for Sewer Collection System Rehabilitation

- PACP NASSCO Pipeline Assessment & Certification Program

2.3 ISO Standard

- ISO 17025 General requirements for the competence of testing and calibration laboratories

2.3 ISO Standard

anchor screws; CIPP; connection seal; cured in place liner; end seal sleeve; leading edge; mechanical fastener; O -Ring; seamless molded hydrophilic gasket (SMHG); sectional liner; watertight seal