T-Liner Steam System

- Home

- /T-Liner Steam System

T-Liner 5-Line, Mobile Steam Unit, Turn-Key Package

The T-Liner® ASTM F2561 compliant system extends up the lateral pipe, beyond the first joint and typically to the right-of-way or to the house, and provides a full-circle; one-piece structural connection with Insignia® hydrophilic compression gasket sealing and engineered tapered ends. The T-Liner provides the best main-to-lateral lining system available today with the only verifiable sealing system.

Track Mounted Portable 5-Line Hose Reel

LMK 5-Line Hose Reel, robotic controls, 500’ of 5-line bonded hose (4-hydraulic and 1-pneumatic) with an internal 5-Line rotary fluid passage, hydraulic auto level-rewind and accessories are mounted on a hydraulic track system

- 8-HP gasoline powered hydraulic power pack with variable flow controls

- A 2,000 watt powered generator

- Fully functional directional traffic warning light and mounted flood lights.

- 110-volt air compressor

- Enclosed day light color monitor

- Manual rewind reel/500′ coax

- Main Pipe Size Positioning Device with wheel adapters for 8″, 10″, and 12″ size pipelines

- 8″, 10″, and 12″ Main Pipe Size Positioning Locking Elements (Packer Cans and Bladders)

- 5-line top roller/ pneumatic 5-line bottom roller

- Self retracting air hose reel 1/4″ x 25′

- Fire extinguisher

- First Aid Kit, Eye Wash Bottle, Umbrella

Steam Equipment – Mobile Steam Unit (Container on Trailer)

The LMK Mobile Steam Unit can be placed where you need it while not tying up a vehicle. The corrugated steel shipping container makes the ideal housing and contains everything needed to steam cure LMK’s T-Liner® Main-to-Lateral Connection Liners. Steam unit includes all piping, electrical and equipment listed below mounted and completely ready for field use.

- Down Stream Reel 500′ of sleeved 1″ and ½” steam hose reel with rotary fluid passage, pneumatic auto level-rewind, and direct chain drive.

- 20-HP diesel fired steam boiler

- 12-KW Whisper-Watt diesel powered generator

- 250 CFM BOSS diesel powered screw air compressor

- Electric air cooling system

- Enclosed water resistant daylight viewable color monitor

- Manual rewind reel/500′ coax

- 400 gallon poly water tank

- Top roller/ Pneumatic bottom roller

- Self retracting air hose reel 1/4″ x 25′

- Manual Rewind Single Inversion Rope Reel with 600′ of 5/16″ Inversion Rope

- Electric 3,500 psi pressure washer hose and reel

- 12 (qty) 24″ reflective traffic cones

- Fire extinguisher

- First Aid Kit

- Eye wash bottle

LMK CIPP T-Liner Wet Out Trailer – 28 ft.

Tailer is complete with a 48″ side door, full ramp rear door, and 7,000 lb axles. Trailer is wired with 50 AMP breaker box, (5) fluorescent ceiling lights, 7′ 6″ ceiling and 3-way switches. Powered by an 7-KW super quiet external fill gasoline fired generator. (Generator is mounted inside the trailer in protective box)

- Wet Out Starter Kit: Digital Thermometer Gun, Grommet Gun, Grommets, Quick Bands, Liner Wet Out Clamp, 2-Slug Rollers 1 with and 1 without Calibration Rings, digital pound scale and digital gram scale and T-Launcher stand

- Tool Box (mounted) with Universal Tool Kit

- Hard wired vacuum pump 1.1 CFM @ 25″ of mercury (mounted on shelf)

- Interior receptacles (Qty. 7)

- Fold down aluminum wet out tables

- Mixing drill, mixing paddle and holder with resin catch, digital scales for 5-Gallon Pails, Promoter and Catalyst

- Deep freezer (25 cubic feet)

- (2) Roof top air conditioners and heat strips (15 amp per unit)

- PVC walls/ceiling, Insulated walls, ceiling, floor, grey rubber floor covering

- LMK EZ Jack

- LMK Ramp Door Bridge

- Flush mount floor tie downs (Qty. 10)

- Matching spare tire (mounted)

- Fire extinguisher, first aid kit, PPE kit and eye wash station

- Storage shelf, marker board, markers and miscellaneous holders installed

Layflat Hose Assembly

- (2) 10′ Layflat Assembly for up to 5′ Liners

- (2) 25′ Layflat Assembly for up to 20′ Liners

- (2) 35′ Layflat Assembly for up to 30′

Cleanout Equipment

- Push Plug, Cleanout, downstream, Steam “B” Station, with ½ inch flow thru, for 4″ – 6″ diameter pipes, hose and regulator assembly

- Push Plug, Cleanout, upstream, non-flow thru, 3″ – 6″, with hose and regulator assembly

T-Launcher for use with 5-Line Equipment

- (2) 8 inch Non-Flow Thru T-Launcher with 5-Line Positioner Tab, includes male camlock and 18″ layflat hose assembly.

- (2) 10 inch Flow Thru T-Launcher with 5-Line Positioner Tab, includes male camlock and 18″ layflat hose assembly.

- (2) 12 inch Flow Thru T-Launcher with 5-Line Positioner Tab, includes male camlock and 18″ layflat hose assembly.

Training

- License Fee per Territory (State), T-Liner

- (4) Days Training, Charge per Day, T-Liner, In-House at LMK’s Facility. Minimum 4 training days required. Trainees: Minimum 4, Maximum 8. LMK will provide all necessary training materials. Continental breakfast and lunch will also be provided. 2 Trainers

- (4) Days Training, Charge per Day, T-Liner, at Customer Location/Jobsite. Minimum 4 training days required. Trainees: minimum 4, maximum 8. Field Training must be scheduled to occur within 60 days from In-House Training. 2 Trainers

- Travel Expenses for Two LMK Technicians/Trainers – Airfare (Economy or Coach) and/or Rental Car – will be added to order when travel is completed

- (2) Travel Mobilization Time / per Trainer – Within Continental US

Optional T-Liner No Cleanout (TLNC) Camera & Positioning System

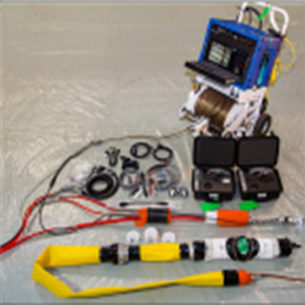

T-Liner No Cleanout (TLNC) Camera and Positioning System

$93,730.00

Complete camera system with two cameras, 15″ stroke LMK positioner with 8″ packer element, air hose and 5-Line hydraulic hoses with ends, camera bracket and pins, complete 8″ flow thru T-launcher with male cam lock hose assembly, layflat hose and end cone assembly with steam back, laser guide and female cam lock positioner spacers (total of 8 of varying sizes) and cable strain relief with ends.

SYSTEM INCLUDES:

- Camera/Reel System

- Spare Camera

- Modified Positioner with packer locking element, air hose and 5-Line hydraulic hoses with ends

- Camera Bracket and pins (fits between T-Launcher and positioner)

- 8″ Flow Thru T-Launcher with 18″ Layflat Hose Assembly with 4″ male camlock

- Laser Guide

- Layflat hose assembly for 3 ft. liners with 4″ female camlock, layflat hose, end cone, inversion rope and 20 ft of steam back hose

- Enclosed day light color monitor

- Positioner spacers Qty 4 – 1 inch, Qty 4 – 3/4 inch, Qty 4 – 1/2 inch

- Cable strain relief with 1/8 inch coated ends

- One quart of TPU Bladder Tab Adhesive

- One bottle of Hydrophilic Glue (needed for installing O-Rings)

- Extra pins for the camera bracket (order 2)

- TLNC Positioner Hose Assembly – 1 set of 5-Line style positioner hoses for the rotation only (2 hoses bonded together with ends cut to length)